Construction in India with Turnkey Applications

Table of Contents

- Warehouses and Storage Facilities

- Factory Sheds and Manufacturing Units

- Cold Storage and Agro Facilities

- Multi-Storied Industrial Buildings

- Structural Support Systems

- Logistics and Loading Bays

- Power Plant and Utility Buildings

- Customized PEB Solutions for Specialized Plants

- Rapid Deployment Projects

- Why AB Engineering Leads in Steel Construction

- FAQs

Introduction

In today’s time, industrial development in India is moving super fast — and you know what’s playing a big role? Steel. Be it godowns, factories or logistic hubs, steel is the material that makes things happen. From Bhubaneswar till Gujarat side, everyone going for steel now—it’s fast, strong, and not too heavy on pocket also.

But see, steel isn’t only about strength. It also gives freedom in design, saves energy, and supports full turnkey execution. At AB Engineering, we’ve done so many projects using steel and seen how much difference it makes. In this blog, let’s see how steel is fully changing the scene in industrial construction.

1. Warehouses and Storage Facilities

Nowadays, with retail and delivery going full speed, India need modern type storage spaces. Steel-made warehouses are just right for that. Whether it’s for FMCG goods or chilled items, PEBs (Pre-Engineered Buildings) help with quick setup and solid strength.

In our Decobee Warehouse Project, we used steel’s long span feature to make a flexible storage setup, one that can grow as the business grows.

Why people choose steel :

- Fast construction, less site mess .

- Easy to expand later .

- Handles big loads without tension .

- Roofs that save energy .

2. Factory Sheds and Manufacturing Units

Earlier, factory sheds meant simple tin roofs. But whats now ? Now they are high-tech production houses with heavy machines and complex setups. Steel makes these modern factories possible.

We made the Floura Fountain Factory using high-span steel design, almost no columns, and weather-safe structure — perfect for big production.

Steel helps with :

- Large column-free spaces

- No vibration issue for machines

- Easy crane support and utility fittings

- Solid protection from all weather

3. Cold Storage and Agro Facilities

For storing food items like grains, fruits, milk, seafood — cold storage is a must. And steel is just right for this job. It keeps everything tight, insulated, and stays strong for long time.

In our Millet Factory project, we used steel to manage temperature, control moisture, and also to keep hygiene in check.

Steel advantages for cold storage:

- Tight panels for better insulation

- Galvalume sheets won’t rust

- Multiple temp zones possible

- Customizable zoning (multiple temp zones)

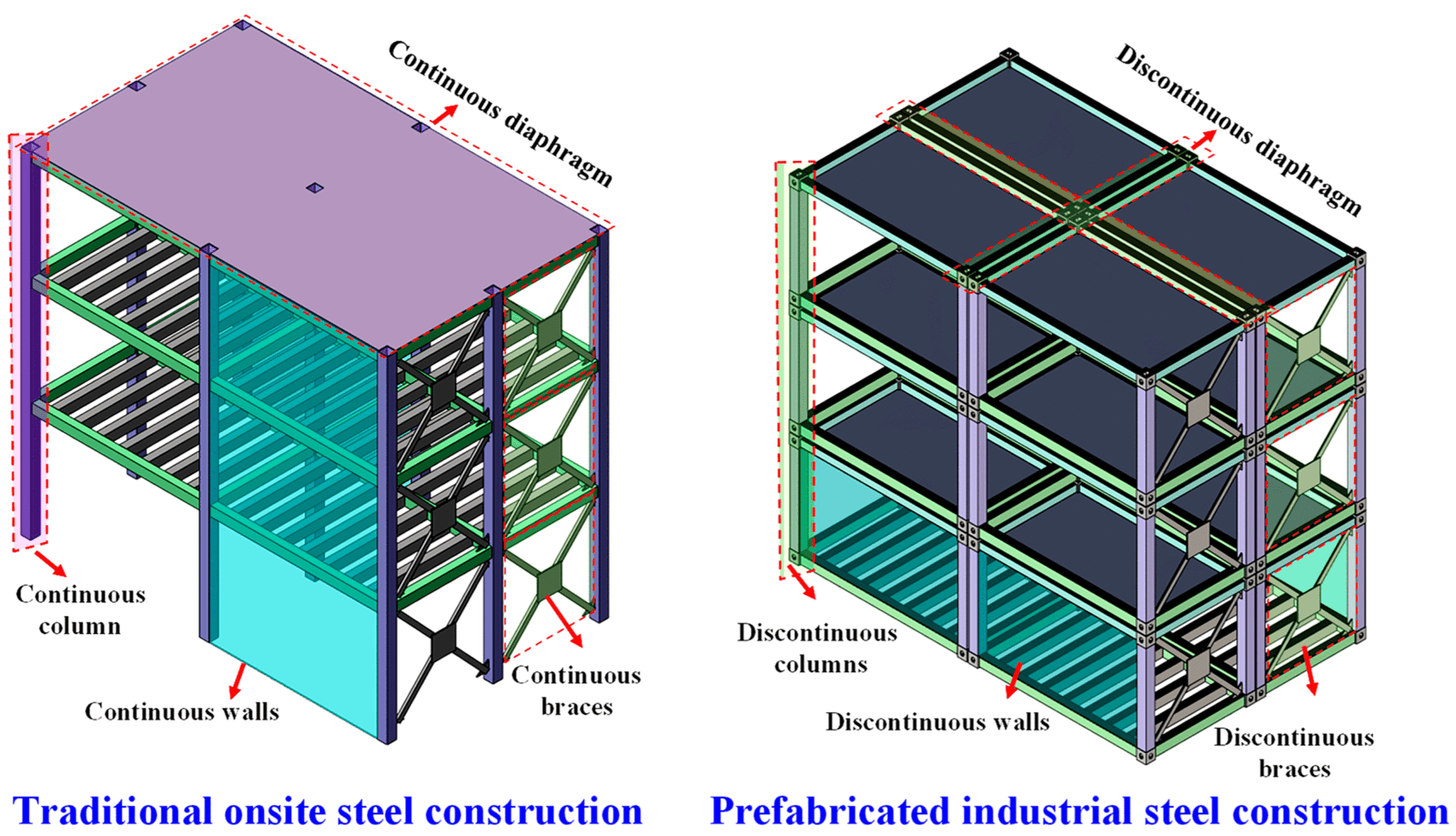

4. Multi-Storied Industrial Buildings

In city areas where land is costly, going up is better than going wide. Steel allows vertical building — ideal for pharma, textiles, electronics, and even showrooms.

We did Zudio Retail buildings like this. Fast work, modern look, and full strength.

Steel advantages:

- Lightweight load on foundation

- Modular steel assembly = faster floors

- Space-efficient layouts

- Seamless integration of elevators, ducts, fire systems

5. Structural Support Systems

Steel is the backbone of industrial strength — literally. In any facility, the beams, columns, trusses, and purlins made of steel define the load-bearing system that supports everything else.

These elements ensure:

- Long-term structural stability

- Resistance to wind, seismic forces, and load vibrations

- Speedy assembly with high precision

- Minimal maintenance with maximum lifespan

6. Logistics and Loading Bays

In logistics hubs, steel allows the construction of large-span loading bays, covered canopies, and dock shelters — all essential for efficient goods movement and material handling.

Steel enables:

- Large open areas with no columns interrupting truck movement

- High canopies for weather-safe loading/unloading

- Prefabricated ramps, platforms, and mezzanines (optional)

- Custom roofing angles for water drainage and thermal control

These structures are often part of AB Engineering’s warehouse and distribution center projects, providing high-speed delivery solutions to logistics clients.

7. Power Plant and Utility Buildings

Steel’s durability, fire resistance, and design adaptability make it ideal for power generation facilities, utility enclosures, and equipment shelters.

Used for:

- Generator buildings, transformer sheds

- Control rooms, switchgear cabins

- Chemical storage spaces

- Water treatment plant setups

Steel makes life easier here — you can run MEP lines smoothly, apply fire-safe coatings without stress, and even expand later if needed. It helps meet both function and safety side without much headache.

8. Customized PEB Solutions for Specialized Plants

Food processing, pharma, packaging — these industries don’t work in one-size-fits-all buildings. They need something made as per their exact setup. Steel handles that job perfectly.

With PEB, AB Engineering offers:

- Room-by-room layout customization

- Integration of mezzanine floors, ventilation systems, skylights

- Fast track schedules with staged fabrication

- High-quality finishes suitable for HACCP, GMP, or ISO environments

Our Floura Fountain and Millet Factory projects both feature unique design configurations created through custom steel modules.

9. Rapid Deployment Projects

Steel enables rapid infrastructure response — critical for government agencies, mining camps, military use, and disaster recovery zones.

Advantages include :

- Pre-cut components that allow fast site assembly

- Bolt-on type expansion — just add more when needed

- Easy to move or dismantle (for temporary or mobile use)

- Works even in remoteplaces with low outside support

Best use cases :

- Emergency storage, field hospitals, labour camps, transport depots, etc.

10. Why AB Engineering Leads in Steel-Based Industrial Constructions

At AB Engineering, steel is not just material — it’s something we truly understand and work with every single day. Our in-house team has design pros, structuralengineers, and on-ground fabricators who know how to turn a plan into reality, smoothly and fast.

Whether it’s a PEB warehouse in Odisha, a multi-storied retail building, or a full turnkey factory project, we mix expert engineering withhands-on experience — using steel

What makes us different :

- End-to-end execution: From Design → Fabrication → Erection → Final Handover

- Custom PEB solutions made to match different industries

- Proven track record with successful projects like Decobee, Millet Factory, Floura Fountain, IIMT CSIR, Zudio/V2 Retail

- Strong presence in Odisha and now expandingacross India

Explore Our Services :

Planning Your Next Industrial Space ?

If you’re thinking to build with steel, AB Engineering has the team, speed,and skill to get your work done right — from the first drawing till the final bolt.

Frequently Asked Questions

Steel offers speed, durability, earthquake resistance, and cost-effectiveness — making it ideal for India’s fast-growing industrial sectors.

Steel is used in factory sheds, mezzanine floors, crane supports, equipment platforms, and external enclosures.

Absolutely. PEB steel buildings can be designed with zoning, insulation, clean room requirements, and fire safety in mind.

Depending on size, most PEB turnkey projects can be completed 30–40% faster than conventional RCC construction.

Recent News

Why PEB Are Reshaping Industrial Infrastructure in India

Innovating Cottage Construction with AB Engineering